No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Antenna Test Turntables

- EMC Test Equipment

- Transient Generators

- RF Power Amplifiers

- DC - 300 kHz RF Amplifiers

- 10 kHz - 250 MHz RF Amplifiers

- 10 kHz - 400 MHz RF Amplifiers

- 10 kHz - 1 GHz RF Amplifiers

- 80 MHz - 1 GHz RF Amplifiers

- 1 GHz - 2 GHz RF Amplifiers

- 700 MHz - 4.2 GHz RF Amplifiers

- 1 GHz - 6 GHz RF Amplifiers

- 2 GHz - 8 GHz RF Amplifiers

- 6 GHz - 18 GHz RF Amplifiers

- 18 GHz - 40 GHz RF Amplifiers

- Pulse Amplifiers

- RF Field Strength Probes & Meters

- RF Conducted Immunity

- EMC Receivers/EMI Analyzers

- EMC Antennas

- Coupling Decoupling Networks (CDN's)

- Line Impedance Stabilization Networks (LISN's)

- RF Test Equipment

- EMC Probes

- EMC Measurement & Equipment Software

- Power Supplies

- Electrical Safety Analyzers

- High Precision Laboratory Power Analyzers & Meters

- Anechoic Chambers

- Over-the-Air (OTA) Test Chambers

- EMI RF Shielded Tent Enclosures

- RF Shielded Rooms

- EMC Absorber

- Positioning Equipment

- EMC/EMI Test Setup

- GTEM Cells / TEM Cells

- Reverberation Chambers

- Used RF Anechoic Chambers

- EMC Chamber Filters

- EMC Chamber Shielding Gaskets

- RF Shielded Doors

- Anechoic Chamber Accessories

- Fully Anechoic (FAR) Test Chambers

- Manufacturers

- 3ctest

- AE Techron

- AH Systems

- Amplifier Research

- Boonton

- Com-Power

- Diamond Engineering

- EM Test (Ametek CTS)

- EMC Partner

- EMC Test Design

- Empower High Power RF Amplifiers

- ETS-lindgren

- Log Periodic Dipole Array Antenna

- Near Field Probe Sets

- Double Ridge Horn Antennas

- Biconical Antennas

- Quad Ridge Horn Antennas

- Electric Field Probes

- GTEM's

- Positioners & Tripods

- Loop Antennas

- Biconilog Antennas

- LISN's (Line Impedance Stabilization Network)

- Shielded Enclosures/Rooms

- Monopole Antennas

- Field Generating Antennas

- Fischer Custom Communications

- Haefely Hipotronics

- Haefely EFT/Burst Immunity Test Systems

- Haefely Surge Combination Wave Test Systems

- Haefely Surge Damped Oscillating Wave Test Systems

- Haefely Electrostatic Discharge Test Systems (ESD)

- Haefely Surge Ring Wave Test Systems

- Haefely Surge Telecom Wave Test Systems

- Haefely Magnetic Field Test Systems

- Haefely CDN's (Coupling/Decoupling Networks)

- IFI Amplifiers

- Keysight (Agilent)

- MVG - Microwave Vision Group

- PMM / Narda

- Rohde & Schwarz RF Test Equipment

- Rohde & Schwarz Broadband RF Amplifiers

- Rohde & Schwarz Spectrum Analyzers

- Rohde & Schwarz Compliant EMI Test Receivers

- Rohde & Schwarz Isotropic RF Probes

- Rohde & Schwarz RF Signal Generators

- Rohde & Schwarz RF Switches

- Rohde & Schwarz Oscilloscopes

- Rohde & Schwarz RF Power Meters

- Rohde & Schwarz RF Power Sensors

- Schloder

- Schwarzbeck Mess-Elektronik

- Schwarzbeck Antennas

- Schwarzbeck Automotive Antennas

- Schwarzbeck Broadband Horn Antennas

- Schwarzbeck Biconical Antennas

- Schwarzbeck Logarithmic Periodic Broadband Antennas

- Schwarzbeck Stacked Log-Periodic Broadband Antennas

- Schwarzbeck Biconic Log-Periodic Antennas

- Schwarzbeck Dipole Antennas

- Schwarzbeck Rod Antennas

- Schwarbeck Antenna Baluns / Holders

- Schwarzbeck LISN Line Impedance Stabilisation Networks

- Schwarbeck Decoupling & Absorbing Clamps

- Schwarzbeck Field Probes

- Schwarzbeck Helmholtz Coils

- Schwarzbeck Antenna Masts

- Schwarzbeck Coupling/Decoupling Networks

- Schwarzbeck Antennas

- Solar Electronics

- Teseq (Schaffner)

- Teseq Automotive Transient Generators

- Teseq RF Test Equipment

- Teseq EFT/Burst Generators

- Teseq RF Immunity Generators

- Teseq ESD Guns

- Teseq Surge Generators

- Teseq Harmonics & Flicker Solutions

- Teseq Dips, Interrupts & Variations Equipment

- Teseq Ring Wave Generators

- Teseq Oscillatory Waves Generators

- Teseq Absorbing Clamps / Ferrite Tube

- Teseq EMC Antennas

- Teseq Current Probes

- Teseq Coupling Networks

- Thermo Keytek

- Vicreate

- Compliance Standards

- International (IEC/EN)

- EN/IEC 61000-3-2

- EN/IEC 61000-3-3

- IEC 61000-3-11

- IEC / EN 610000-3-12

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-7

- EN/IEC 61000-4-8

- EN/IEC 61000-4-9

- EN/IEC 61000-4-10

- EN/IEC 61000-4-11

- EN/IEC 61000-4-12

- EN/IEC 61000-4-16

- EN/IEC 61000-4-18

- EN/IEC 61000-4-19

- EN/IEC 61000-4-20

- EN/IEC 61000-4-21

- EN/IEC 61000-4-29

- EN/IEC 61000-4-31

- IEC 61000-4-39

- EN/IEC 62132

- SEMI F47 Voltage Sag Immunity

- Product Standards

- Military & Aerospace Standards

- Automotive EMC Standards

- CISPR Standards

- Telecom Testing

- ANSI/IEEE Standards

- FCC Part 15

- FCC Part 30

- International (IEC/EN)

- Application/Test Type

- Radiated Immunity

- Bulk Current Injection Testing

- RF Emissions Testing

- Conducted Immunity

- Conducted Emissions

- Antenna Pattern Measurement

- CE Mark Testing

- Intentional Radiator Testing

- Pulsed HIRF Radar

- Over-the-Air (OTA) Testing

- 5G Test Solutions

- Automotive EMC

- SAR Measurement Equipment

- Radiated Emissions

- Battery Simulator Test Equipment

- Services

- Clearance

Viewed products

-

Maturo TT 6.0-10t...

6.0 m Diameter Especially designed...

View larger

View larger Maturo TT 6.0-10t Turntable

New

- 6.0 m Diameter

- Especially designed for flush mounted installation in semi anechoic electromagnetic absorption chambers.

- Carrier plate is made of stainless steel.

- A 290 mm diameter opening in the centre of the turntable;

- Provides the capability to insert power supply for testing.

Test Equipment Description

The turntable TT 6.0-10t is especially designed for flush mounted installation in semi anechoic electromagnetic absorption chambers. The carrier plate is made of stainless steel.

A 290 mm diameter opening in the centre of the turntable provides the capability to insert power supply for testing.

The IEEE 488.2 (GPIB) bus provides an additional control option for all functions, when operated with the SCU/MCU or NCD Controller.

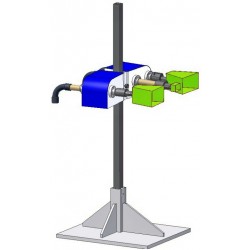

Fig.: Drive unit assembly of turntable

Power supply in the centre of the turntable:

It is possible to integrate various types of connectors for the power supply of the EUT

|  |

| Figure: Power supply in the centre for EUT | |

Limit switches:

The turntable is equipped with a limit switch and positioning switch system to guarantee the exact positioning of the turntable. An “overturning” of the system is prevented by using limit switches.

Connection to the ground plane:

There is a long-lasting, maintenance-free contact systems included: Material: hollow core copper beryllium tubing.

|  |

| Figure: Contact system between the turntables and to the ground plane | |

Covering and tolerances:

The covering is made of stainless steel, the gap between the turntable and the ground plane less than 5 mm.

The radial run out is within a tolerance of +/- 3 mm.

The height differences are within a range of 10 mm or better.

|  |

| Figure: Level system of turntable for height adjustment | |

| |

| Figure: Stainless steel cover plates | |

Turntable structure:

Solid welded steel construction; parts are assembled with screws (for easy transportation). The complete structure is galvanised for long-lasting performance of the system.

Figure: Turntable structure made of solid welded galvanised steel

Further specifications and options available upon request

The following options are available upon request:

- Power supply in the centre with different connectors

- External power supply outside the centre with energy chain

- Continuous rotation with integrated slip rings or rotary joints

- Integrated exhaust gas extraction system

- Higher positioning accuracy

- Outdoor applications

| Technical Data | |

| Diameter | 6.0 m |

| Permissible load | 10.000 kg |

| Point load | 1.250 kg (at area of 10cm x 10cm) |

| Total height | min. 800 mm |

| Material carrier plate | Stainless Steel |

| Rotating speed adjustable between | 0.3 to 1.0 rpm |

| Rotating angle | +400°/-200° |

| Positioning accuracy | +/- 0.5° |

| Turntable drive | Helical-bevel gear |

| Motor | Servo motor, frequency inverter |

| Interference suppression | 20 dB under limits EN 55022 class B |

| Control cable | Plastic optical fibre cable 980/1000 µm |

| Attenuation of fibre cable | 625 nm |

| Remote control via | IEEE interface |

| Current consumption | max. 32 A |

| Voltage | 380-400 VAC, 50/60 Hz, 3-phase |

| Concentricity tolerance | +/- 3 mm |

| Elevation tolerance less than | 5 mm |

| Ground plane connecting every | 50 mm |

| Square border interface (Easy fitting into Groundplane of chamber) | 6.5 m x 6.5 m |

| Temperature range | +10°C to +35°C |

| Total weight | approx. 9.000 kg |

| Accessories | Interface to SCU/MCU/NCD Controller 1.5 m power supply cable Service manual |