No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Truncated Pyramidal Microwave Absorber

- EMC Test Equipment

- Transient Generators

- RF Power Amplifiers

- DC - 300 kHz RF Amplifiers

- 10 kHz - 250 MHz RF Amplifiers

- 10 kHz - 400 MHz RF Amplifiers

- 10 kHz - 1 GHz RF Amplifiers

- 80 MHz - 1 GHz RF Amplifiers

- 1 GHz - 2 GHz RF Amplifiers

- 700 MHz - 4.2 GHz RF Amplifiers

- 1 GHz - 6 GHz RF Amplifiers

- 2 GHz - 8 GHz RF Amplifiers

- 6 GHz - 18 GHz RF Amplifiers

- 18 GHz - 40 GHz RF Amplifiers

- Pulse Amplifiers

- RF Field Strength Probes & Meters

- RF Conducted Immunity

- EMC Receivers/EMI Analyzers

- EMC Antennas

- Coupling Decoupling Networks (CDN's)

- Line Impedance Stabilization Networks (LISN's)

- RF Test Equipment

- EMC Probes

- EMC Measurement & Equipment Software

- Power Supplies

- Electrical Safety Analyzers

- High Precision Laboratory Power Analyzers & Meters

- Anechoic Chambers

- Over-the-Air (OTA) Test Chambers

- EMI RF Shielded Tent Enclosures

- RF Shielded Rooms

- EMC Absorber

- Positioning Equipment

- EMC/EMI Test Setup

- GTEM Cells / TEM Cells

- Reverberation Chambers

- Used RF Anechoic Chambers

- EMC Chamber Filters

- EMC Chamber Shielding Gaskets

- RF Shielded Doors

- Anechoic Chamber Accessories

- Fully Anechoic (FAR) Test Chambers

- Manufacturers

- 3ctest

- AE Techron

- AH Systems

- Amplifier Research

- Boonton

- Com-Power

- Diamond Engineering

- EM Test (Ametek CTS)

- EMC Partner

- EMC Test Design

- Empower High Power RF Amplifiers

- ETS-lindgren

- Log Periodic Dipole Array Antenna

- Near Field Probe Sets

- Double Ridge Horn Antennas

- Biconical Antennas

- Quad Ridge Horn Antennas

- Electric Field Probes

- GTEM's

- Positioners & Tripods

- Loop Antennas

- Biconilog Antennas

- LISN's (Line Impedance Stabilization Network)

- Shielded Enclosures/Rooms

- Monopole Antennas

- Field Generating Antennas

- Fischer Custom Communications

- Haefely Hipotronics

- Haefely EFT/Burst Immunity Test Systems

- Haefely Surge Combination Wave Test Systems

- Haefely Surge Damped Oscillating Wave Test Systems

- Haefely Electrostatic Discharge Test Systems (ESD)

- Haefely Surge Ring Wave Test Systems

- Haefely Surge Telecom Wave Test Systems

- Haefely Magnetic Field Test Systems

- Haefely CDN's (Coupling/Decoupling Networks)

- IFI Amplifiers

- Keysight (Agilent)

- MVG - Microwave Vision Group

- PMM / Narda

- Rohde & Schwarz RF Test Equipment

- Rohde & Schwarz Broadband RF Amplifiers

- Rohde & Schwarz Spectrum Analyzers

- Rohde & Schwarz Compliant EMI Test Receivers

- Rohde & Schwarz Isotropic RF Probes

- Rohde & Schwarz RF Signal Generators

- Rohde & Schwarz RF Switches

- Rohde & Schwarz Oscilloscopes

- Rohde & Schwarz RF Power Meters

- Rohde & Schwarz RF Power Sensors

- Schloder

- Schwarzbeck Mess-Elektronik

- Schwarzbeck Antennas

- Schwarzbeck Automotive Antennas

- Schwarzbeck Broadband Horn Antennas

- Schwarzbeck Biconical Antennas

- Schwarzbeck Logarithmic Periodic Broadband Antennas

- Schwarzbeck Stacked Log-Periodic Broadband Antennas

- Schwarzbeck Biconic Log-Periodic Antennas

- Schwarzbeck Dipole Antennas

- Schwarzbeck Rod Antennas

- Schwarbeck Antenna Baluns / Holders

- Schwarzbeck LISN Line Impedance Stabilisation Networks

- Schwarbeck Decoupling & Absorbing Clamps

- Schwarzbeck Field Probes

- Schwarzbeck Helmholtz Coils

- Schwarzbeck Antenna Masts

- Schwarzbeck Coupling/Decoupling Networks

- Schwarzbeck Antennas

- Solar Electronics

- Teseq (Schaffner)

- Teseq Automotive Transient Generators

- Teseq RF Test Equipment

- Teseq EFT/Burst Generators

- Teseq RF Immunity Generators

- Teseq ESD Guns

- Teseq Surge Generators

- Teseq Harmonics & Flicker Solutions

- Teseq Dips, Interrupts & Variations Equipment

- Teseq Ring Wave Generators

- Teseq Oscillatory Waves Generators

- Teseq Absorbing Clamps / Ferrite Tube

- Teseq EMC Antennas

- Teseq Current Probes

- Teseq Coupling Networks

- Thermo Keytek

- Vicreate

- Compliance Standards

- International (IEC/EN)

- EN/IEC 61000-3-2

- EN/IEC 61000-3-3

- IEC 61000-3-11

- IEC / EN 610000-3-12

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-7

- EN/IEC 61000-4-8

- EN/IEC 61000-4-9

- EN/IEC 61000-4-10

- EN/IEC 61000-4-11

- EN/IEC 61000-4-12

- EN/IEC 61000-4-16

- EN/IEC 61000-4-18

- EN/IEC 61000-4-19

- EN/IEC 61000-4-20

- EN/IEC 61000-4-21

- EN/IEC 61000-4-29

- EN/IEC 61000-4-31

- IEC 61000-4-39

- EN/IEC 62132

- SEMI F47 Voltage Sag Immunity

- Product Standards

- Military & Aerospace Standards

- Automotive EMC Standards

- CISPR Standards

- Telecom Testing

- ANSI/IEEE Standards

- FCC Part 15

- FCC Part 30

- International (IEC/EN)

- Application/Test Type

- Radiated Immunity

- Bulk Current Injection Testing

- RF Emissions Testing

- Conducted Immunity

- Conducted Emissions

- Antenna Pattern Measurement

- CE Mark Testing

- Intentional Radiator Testing

- Pulsed HIRF Radar

- Over-the-Air (OTA) Testing

- 5G Test Solutions

- Automotive EMC

- SAR Measurement Equipment

- Radiated Emissions

- Battery Simulator Test Equipment

- Services

- Clearance

Viewed products

-

Cuming Microwave C-RAM...

1 - 35 GHz Frequency Range Is a thin,...

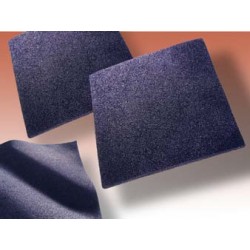

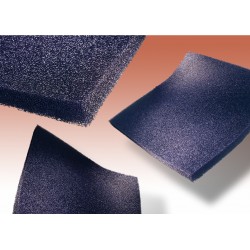

Cuming Microwave C-RAM GDX High Loss Silicone Rubber Microwave Absorber Sheet

New

- 1 - 35 GHz Frequency Range

- Is a thin, magnetically filled rubber sheet stock

- It is applied to metal surfaces to attenuate RF surface current

- It can be used to modify antenna patterns, lower the Q of a cavity, act as a transmission line attenuator

- Modify the radar cross section of targets

PDF Downloads

Test Equipment Description

C-RAM GDX is a thin, magnetically filled rubber sheet stock which has high loss at microwave frequencies from 1 to 35 GHz. It is applied to metal surfaces to attenuate RF surface currents. It can be used to modify antenna patterns, lower the Q of a cavity, act as a transmission line attenuator and modify the radar cross section of targets.

C-RAM GDX is thin and elastomeric, so it will conform to curvatures of the substrate. It is not electrically conductive, and has high dielectric strength. It is a soft material and is readily diecut or cut with a razor. Being based on a silicone rubber, it will withstand wide temperature ranges, and survive outdoor exposure.

C-RAM GDX has a high magnetic loss tangent from 1 GHz to 18 GHz. Thicker grades are required to attenuate at lower frequencies to obtain the same performance as a thinner grade at higher frequencies.

C-RAM GDX is available in silicone or urethane elastomers. Please refer to Technical Bulletin No. 310-1 for properties and benefits of each type of elastomer.

METHOD OF APPLICATION

The normal method of applying C-RAM GDX to a substrate is with a silicone RTV adhesive. For best results, the metal should be scuffed with sandpaper, wiped with alcohol to remove dust and grease, and have a silicone primer applied, such as C-PRIME 215.

The silicone adhesive, such as C-BOND 255 or equivalent, is brushed or rolled onto one of the surfaces, and the sheet is then applied to the metal. An overnight cure is generally required, and a modest temperature cycle, such as a few hours at 150o F, helps the bond.

As an alternative, C-RAM GDX can be supplied with a pressure sensitive adhesive, which, while not as strong as an RTV adhesive, will provide an adequate bond in many applications, particularly when one is bonding several smaller pieces. Simply peel off the backing, stick the part to a primed surface, and apply heat with a heat gun for 1-2 minutes to effect a good bond.

| TYPICAL PROPERTIES | |

| Color | Grey |

| Flammability | non-flammable |

| Thickness and weight (3 grades) | 0.75 mm (.030”) --- 2.3 kg/m2 (0.47 lb/ft2) 1.52 mm (.060”) --- 4.6 kg/m2 (0.95 lb/ft2) 3.18 mm (.125”) --- 9.6 kg/m2 (1.98 lb/ft2) |

| Service temperature | 65°C (150°F |

| Hardness, Shore A | 80 |

AVAILABILITY

C-RAM GDX is available in three standard thicknesses-- .030”, .060”, and .125”.

Standard dimensions for all thicknesses are flat sheets 300 x 300 mm (12 x 12 in) and 400 x 500 mm (16 x 20 in), in the nominal thickness for the particular grade. Specify the part as: CRAM GDX-xxx, where xxx is the nominal thickness in inches (030, 060,125), and include the dimensions.

We can supply other dimensions, and can diecut or laser-cut parts to your drawings.

C-RAM GDX can also be supplied with a peeland-stick pressure sensitive adhesive backing (specify by adding a /PSA suffix to the part name).