No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Truncated Pyramidal Microwave Absorber

- EMC Test Equipment

- Transient Generators

- RF Power Amplifiers

- DC - 300 kHz RF Amplifiers

- 10 kHz - 250 MHz RF Amplifiers

- 10 kHz - 400 MHz RF Amplifiers

- 10 kHz - 1 GHz RF Amplifiers

- 80 MHz - 1 GHz RF Amplifiers

- 1 GHz - 2 GHz RF Amplifiers

- 700 MHz - 4.2 GHz RF Amplifiers

- 1 GHz - 6 GHz RF Amplifiers

- 2 GHz - 8 GHz RF Amplifiers

- 6 GHz - 18 GHz RF Amplifiers

- 18 GHz - 40 GHz RF Amplifiers

- Pulse Amplifiers

- RF Field Strength Probes & Meters

- RF Conducted Immunity

- EMC Receivers/EMI Analyzers

- EMC Antennas

- Coupling Decoupling Networks (CDN's)

- Line Impedance Stabilization Networks (LISN's)

- RF Test Equipment

- EMC Probes

- EMC Measurement & Equipment Software

- Power Supplies

- Electrical Safety Analyzers

- High Precision Laboratory Power Analyzers & Meters

- Anechoic Chambers

- Over-the-Air (OTA) Test Chambers

- EMI RF Shielded Tent Enclosures

- RF Shielded Rooms

- EMC Absorber

- Positioning Equipment

- EMC/EMI Test Setup

- GTEM Cells / TEM Cells

- Reverberation Chambers

- Used RF Anechoic Chambers

- EMC Chamber Filters

- EMC Chamber Shielding Gaskets

- RF Shielded Doors

- Anechoic Chamber Accessories

- Fully Anechoic (FAR) Test Chambers

- Manufacturers

- 3ctest

- AE Techron

- AH Systems

- Amplifier Research

- Boonton

- Com-Power

- Diamond Engineering

- EM Test (Ametek CTS)

- EMC Partner

- EMC Test Design

- Empower High Power RF Amplifiers

- ETS-lindgren

- Log Periodic Dipole Array Antenna

- Near Field Probe Sets

- Double Ridge Horn Antennas

- Biconical Antennas

- Quad Ridge Horn Antennas

- Electric Field Probes

- GTEM's

- Positioners & Tripods

- Loop Antennas

- Biconilog Antennas

- LISN's (Line Impedance Stabilization Network)

- Shielded Enclosures/Rooms

- Monopole Antennas

- Field Generating Antennas

- Fischer Custom Communications

- Haefely Hipotronics

- Haefely EFT/Burst Immunity Test Systems

- Haefely Surge Combination Wave Test Systems

- Haefely Surge Damped Oscillating Wave Test Systems

- Haefely Electrostatic Discharge Test Systems (ESD)

- Haefely Surge Ring Wave Test Systems

- Haefely Surge Telecom Wave Test Systems

- Haefely Magnetic Field Test Systems

- Haefely CDN's (Coupling/Decoupling Networks)

- IFI Amplifiers

- Keysight (Agilent)

- MVG - Microwave Vision Group

- PMM / Narda

- Rohde & Schwarz RF Test Equipment

- Rohde & Schwarz Broadband RF Amplifiers

- Rohde & Schwarz Spectrum Analyzers

- Rohde & Schwarz Compliant EMI Test Receivers

- Rohde & Schwarz Isotropic RF Probes

- Rohde & Schwarz RF Signal Generators

- Rohde & Schwarz RF Switches

- Rohde & Schwarz Oscilloscopes

- Rohde & Schwarz RF Power Meters

- Rohde & Schwarz RF Power Sensors

- Schloder

- Schwarzbeck Mess-Elektronik

- Schwarzbeck Antennas

- Schwarzbeck Automotive Antennas

- Schwarzbeck Broadband Horn Antennas

- Schwarzbeck Biconical Antennas

- Schwarzbeck Logarithmic Periodic Broadband Antennas

- Schwarzbeck Stacked Log-Periodic Broadband Antennas

- Schwarzbeck Biconic Log-Periodic Antennas

- Schwarzbeck Dipole Antennas

- Schwarzbeck Rod Antennas

- Schwarbeck Antenna Baluns / Holders

- Schwarzbeck LISN Line Impedance Stabilisation Networks

- Schwarbeck Decoupling & Absorbing Clamps

- Schwarzbeck Field Probes

- Schwarzbeck Helmholtz Coils

- Schwarzbeck Antenna Masts

- Schwarzbeck Coupling/Decoupling Networks

- Schwarzbeck Antennas

- Solar Electronics

- Teseq (Schaffner)

- Teseq Automotive Transient Generators

- Teseq RF Test Equipment

- Teseq EFT/Burst Generators

- Teseq RF Immunity Generators

- Teseq ESD Guns

- Teseq Surge Generators

- Teseq Harmonics & Flicker Solutions

- Teseq Dips, Interrupts & Variations Equipment

- Teseq Ring Wave Generators

- Teseq Oscillatory Waves Generators

- Teseq Absorbing Clamps / Ferrite Tube

- Teseq EMC Antennas

- Teseq Current Probes

- Teseq Coupling Networks

- Thermo Keytek

- Vicreate

- Compliance Standards

- International (IEC/EN)

- EN/IEC 61000-3-2

- EN/IEC 61000-3-3

- IEC 61000-3-11

- IEC / EN 610000-3-12

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-7

- EN/IEC 61000-4-8

- EN/IEC 61000-4-9

- EN/IEC 61000-4-10

- EN/IEC 61000-4-11

- EN/IEC 61000-4-12

- EN/IEC 61000-4-16

- EN/IEC 61000-4-18

- EN/IEC 61000-4-19

- EN/IEC 61000-4-20

- EN/IEC 61000-4-21

- EN/IEC 61000-4-29

- EN/IEC 61000-4-31

- IEC 61000-4-39

- EN/IEC 62132

- SEMI F47 Voltage Sag Immunity

- Product Standards

- Military & Aerospace Standards

- Automotive EMC Standards

- CISPR Standards

- Telecom Testing

- ANSI/IEEE Standards

- FCC Part 15

- FCC Part 30

- International (IEC/EN)

- Application/Test Type

- Radiated Immunity

- Bulk Current Injection Testing

- RF Emissions Testing

- Conducted Immunity

- Conducted Emissions

- Antenna Pattern Measurement

- CE Mark Testing

- Intentional Radiator Testing

- Pulsed HIRF Radar

- Over-the-Air (OTA) Testing

- 5G Test Solutions

- Automotive EMC

- SAR Measurement Equipment

- Radiated Emissions

- Battery Simulator Test Equipment

- Services

- Clearance

Viewed products

-

Cuming Microwave C-RAM...

C-RAM MA50 Dielectric-type absorber...

View larger

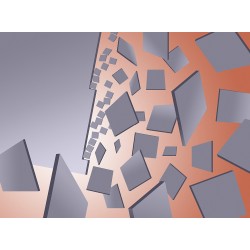

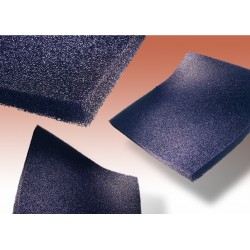

View larger Cuming Microwave C-RAM MA50 and MA55 Microwave Absorbing Plastics

New

C-RAM MA50

- Dielectric-type absorber

- It consists of a highly thixotropic syntactic foam

- Loaded with lightweight lossy fillers

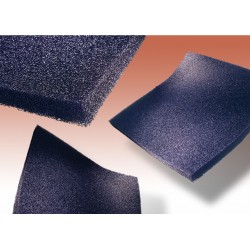

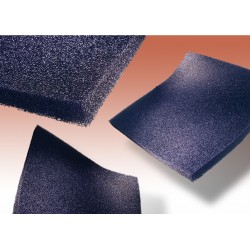

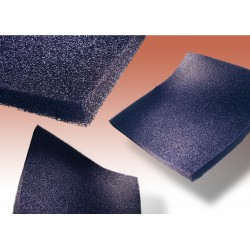

C-RAM MA55

- Magnetic-type absorber

- It is heavily loaded with magnetic fillers to make a thixotropic paste

- Very effective in relatively thin layers

- It is dense (Sp.Gr.=4.0)

- Can add appreciable weight to the host system

- Recommended for control of surface waves

PDF Downloads

Test Equipment Description

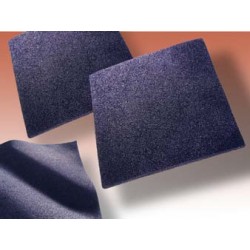

The C-RAM MA50 and MA55 are microwave absorbing mastic pastes which can be applied to vertical or horizontal surfaces. After the mastic cures into a rigid solid, it is impervious to moisture or other environmental effects. C-RAM mastics are intended for the reduction of radar cross section (RCS) of military vehicles and naval vessels as well as control of surface wave, antenna tuning, and many other uses.

C-RAM MA50 is a dielectric-type absorber. It consists of a highly thixotropic syntactic foam (plastic resin and glass microspheres) loaded with lightweight lossy fillers. It is relatively low in density, with a nominal specific weight of 40 lbs./ft3 (Sp.Gr.=0.65).

C-RAM MA55 is a magnetic-type absorber. It is heavily loaded with magnetic fillers to make a thixotropic paste. Although very effective in relatively thin layers, it is dense (Sp.Gr.=4.0) and can add appreciable weight to the host system. Magnetic absorbers are recommended for control of surface waves.

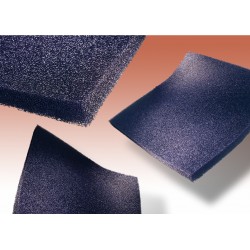

Control of thickness is important, especially for magnetic materials. If no other test data are available, the optimum thickness of the mastic coating should be established by experimentation. Comb-like applicator trowels can be made to apply mastic in “furrows” of controlled thickness. The furrow can then be smoothed out to form a flat surface, or the furrows left intact to promote scattering. The front face of the furrows can be filled in with special materials if desired.

Technical advice is available from Cuming Microwave.

INSTRUCTIONS FOR USE

- Surface to be coated should be clean and dry. A solvent wash, compatible with the substrate, is recommended. The temperature of the surface should be at least +50°F.

- Weigh out only the amount of Part A which can be used within 30 minutes (pot life at room temperature). Add Part B and mix thoroughly. MA50: 38 parts B to 100 parts A (by weight) MA55: 6 parts B to 100 parts A (by weight).

- Apply the mixed material to the prepared surfaces in the required thickness. Hardening time is dependent on temperature: 24 hours at +50°F, 8 hours at +80°F, and 1 hour at +125°F.

Note: the service temperature range is –55 to +120°C (-70 to +250°F). The material should be postcured at a temperature at least as high as its end use temperature.