No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

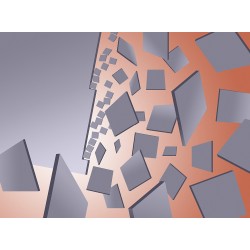

Truncated Pyramidal Microwave Absorber

- EMC Test Equipment

- Transient Generators

- RF Power Amplifiers

- DC - 300 kHz RF Amplifiers

- 10 kHz - 250 MHz RF Amplifiers

- 10 kHz - 400 MHz RF Amplifiers

- 10 kHz - 1 GHz RF Amplifiers

- 80 MHz - 1 GHz RF Amplifiers

- 1 GHz - 2 GHz RF Amplifiers

- 700 MHz - 4.2 GHz RF Amplifiers

- 1 GHz - 6 GHz RF Amplifiers

- 2 GHz - 8 GHz RF Amplifiers

- 6 GHz - 18 GHz RF Amplifiers

- 18 GHz - 40 GHz RF Amplifiers

- Pulse Amplifiers

- RF Field Strength Probes & Meters

- RF Conducted Immunity

- EMC Receivers/EMI Analyzers

- EMC Antennas

- Coupling Decoupling Networks (CDN's)

- Line Impedance Stabilization Networks (LISN's)

- RF Test Equipment

- EMC Probes

- EMC Measurement & Equipment Software

- Power Supplies

- Electrical Safety Analyzers

- High Precision Laboratory Power Analyzers & Meters

- Anechoic Chambers

- Over-the-Air (OTA) Test Chambers

- EMI RF Shielded Tent Enclosures

- RF Shielded Rooms

- EMC Absorber

- Positioning Equipment

- EMC/EMI Test Setup

- GTEM Cells / TEM Cells

- Reverberation Chambers

- Used RF Anechoic Chambers

- EMC Chamber Filters

- EMC Chamber Shielding Gaskets

- RF Shielded Doors

- Anechoic Chamber Accessories

- Fully Anechoic (FAR) Test Chambers

- Manufacturers

- 3ctest

- AE Techron

- AH Systems

- Amplifier Research

- Boonton

- Com-Power

- Diamond Engineering

- EM Test (Ametek CTS)

- EMC Partner

- EMC Test Design

- Empower High Power RF Amplifiers

- ETS-lindgren

- Log Periodic Dipole Array Antenna

- Near Field Probe Sets

- Double Ridge Horn Antennas

- Biconical Antennas

- Quad Ridge Horn Antennas

- Electric Field Probes

- GTEM's

- Positioners & Tripods

- Loop Antennas

- Biconilog Antennas

- LISN's (Line Impedance Stabilization Network)

- Shielded Enclosures/Rooms

- Monopole Antennas

- Field Generating Antennas

- Fischer Custom Communications

- Haefely Hipotronics

- Haefely EFT/Burst Immunity Test Systems

- Haefely Surge Combination Wave Test Systems

- Haefely Surge Damped Oscillating Wave Test Systems

- Haefely Electrostatic Discharge Test Systems (ESD)

- Haefely Surge Ring Wave Test Systems

- Haefely Surge Telecom Wave Test Systems

- Haefely Magnetic Field Test Systems

- Haefely CDN's (Coupling/Decoupling Networks)

- IFI Amplifiers

- Keysight (Agilent)

- MVG - Microwave Vision Group

- PMM / Narda

- Rohde & Schwarz RF Test Equipment

- Rohde & Schwarz Broadband RF Amplifiers

- Rohde & Schwarz Spectrum Analyzers

- Rohde & Schwarz Compliant EMI Test Receivers

- Rohde & Schwarz Isotropic RF Probes

- Rohde & Schwarz RF Signal Generators

- Rohde & Schwarz RF Switches

- Rohde & Schwarz Oscilloscopes

- Rohde & Schwarz RF Power Meters

- Rohde & Schwarz RF Power Sensors

- Schloder

- Schwarzbeck Mess-Elektronik

- Schwarzbeck Antennas

- Schwarzbeck Automotive Antennas

- Schwarzbeck Broadband Horn Antennas

- Schwarzbeck Biconical Antennas

- Schwarzbeck Logarithmic Periodic Broadband Antennas

- Schwarzbeck Stacked Log-Periodic Broadband Antennas

- Schwarzbeck Biconic Log-Periodic Antennas

- Schwarzbeck Dipole Antennas

- Schwarzbeck Rod Antennas

- Schwarbeck Antenna Baluns / Holders

- Schwarzbeck LISN Line Impedance Stabilisation Networks

- Schwarbeck Decoupling & Absorbing Clamps

- Schwarzbeck Field Probes

- Schwarzbeck Helmholtz Coils

- Schwarzbeck Antenna Masts

- Schwarzbeck Coupling/Decoupling Networks

- Schwarzbeck Antennas

- Solar Electronics

- Teseq (Schaffner)

- Teseq Automotive Transient Generators

- Teseq RF Test Equipment

- Teseq EFT/Burst Generators

- Teseq RF Immunity Generators

- Teseq ESD Guns

- Teseq Surge Generators

- Teseq Harmonics & Flicker Solutions

- Teseq Dips, Interrupts & Variations Equipment

- Teseq Ring Wave Generators

- Teseq Oscillatory Waves Generators

- Teseq Absorbing Clamps / Ferrite Tube

- Teseq EMC Antennas

- Teseq Current Probes

- Teseq Coupling Networks

- Thermo Keytek

- Vicreate

- Compliance Standards

- International (IEC/EN)

- EN/IEC 61000-3-2

- EN/IEC 61000-3-3

- IEC 61000-3-11

- IEC / EN 610000-3-12

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-7

- EN/IEC 61000-4-8

- EN/IEC 61000-4-9

- EN/IEC 61000-4-10

- EN/IEC 61000-4-11

- EN/IEC 61000-4-12

- EN/IEC 61000-4-16

- EN/IEC 61000-4-18

- EN/IEC 61000-4-19

- EN/IEC 61000-4-20

- EN/IEC 61000-4-21

- EN/IEC 61000-4-29

- EN/IEC 61000-4-31

- IEC 61000-4-39

- EN/IEC 62132

- SEMI F47 Voltage Sag Immunity

- Product Standards

- Military & Aerospace Standards

- Automotive EMC Standards

- CISPR Standards

- Telecom Testing

- ANSI/IEEE Standards

- FCC Part 15

- FCC Part 30

- International (IEC/EN)

- Application/Test Type

- Radiated Immunity

- Bulk Current Injection Testing

- RF Emissions Testing

- Conducted Immunity

- Conducted Emissions

- Antenna Pattern Measurement

- CE Mark Testing

- Intentional Radiator Testing

- Pulsed HIRF Radar

- Over-the-Air (OTA) Testing

- 5G Test Solutions

- Automotive EMC

- SAR Measurement Equipment

- Radiated Emissions

- Battery Simulator Test Equipment

- Services

- Clearance

Viewed products

-

Cuming Microwave C-RAM...

Series of iron filled epoxy sheet...

-

AH Systems SAS-510-2...

Frequency Range: 290 MHz - 2000 MHz...

View larger

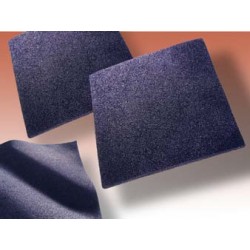

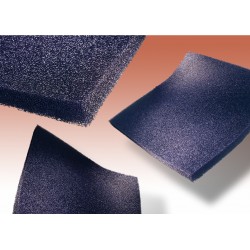

View larger Cuming Microwave C-RAM RGD Rigid Epoxy/Iron Lossy Magnetic Sheet and Rod Stock

New

- Series of iron filled epoxy sheet materials having a high magnetic loss

- Can be machined into terminations

- Loads for attenuators, waveguides, coaxial lines, and microstrip circuits

- It can also be used for lowering the Q of cavities and;

- Eliminating unwanted resonances

PDF Downloads

Test Equipment Description

The C-RAM RGD is a series of iron filled epoxy sheet materials having a high magnetic loss. It is available in several grades, as given in the table below, having a range of permittivities and complex permeabilities.

C-RAM RGD can be machined into terminations and loads for attenuators, waveguides, coaxial lines, and microstrip circuits. It can also be used for lowering the Q of cavities and eliminating unwanted resonances.

C-RAM RGD is a hard epoxy plastic and can be readily sawed, ground, milled or otherwise machined to complex shapes. Since it is ferromagnetic, it is easily held in place with magnetic chucks during machining.

The material has good thermal conductivity and can be used to dissipate heat, including that generated by its own magnetic loss mechanism.

C-RAM KR (see Technical Bulletin 330) is the two component liquid resin version of RGD. It can be mixed, poured and cast into molds or cavities; when cured, it will have the properties of C-RAM RGD.

| TYPICAL PROPERTIES | |

| Color | Grey |

| Specific Gravity | 2.0 to 4.8 |

| Thermal Expansion per °C | 30 x 10-6 |

| Thermal Conductivity | .003 cal-cm/sec-cm2-°C |

| Max. Service Temperature | 180 °C (350°F) |

| Tensile Strength | 560 kg/cm2 (8000 psi) |

| Hardness, Shore D | 85 |

| Water Absorption, 24 hrs | <0.1% |

| Volume Resistivity, ohm-cm | >1011 |

| Dielectric Strength | >1000 v/mm |

| Dielectric Strength, kV/mm | >400 (>100 V/mil) |

MACHINING AND APPLICATION

C-RAM RGD is typically machined into finished parts. It can be readily machined using carbide tools, using techniques similar to machining soft metals. Coolants should be used to prevent the material from overheating. Particular care should be taken not to expose the machining dust to sparks, high heat, or flames, as it can readily burn and/or smolder. A fire extinguisher designed for metal fires (type D) should be kept nearby – do not use water to extinguish burning material.

Finished pieces of C-RAM RGD can be bonded in place using an epoxy adhesive such as CBOND 245. Tapped holes can be machined into parts for mechanical fastening, or tapped metal inserts can be bonded into drilled holes.

| Table of Permittivity and Permeability of C-RAM RGD | ||||||||||

| ------------Properties at 1.0 GHz--------------- | -------------Properties at 10.0 GHz------------- | |||||||||

| e’ | e” | m’ | M” | dB/cm | e’ | e“ | m‘ | m“ | DB/cm | |

| RGD-112 | 6 | 0.24 | 1.4 | .03 | .16 | 4.8 | .19 | 1.1 | .25 | 5.6 |

| RGD-114 | 11 | 0.55 | 2.1 | .17 | .57 | 9.7 | .49 | 1.1 | .44 | 13.2 |

| RGD-116 | 17 | 1.2 | 3.0 | .39 | 1.3 | 16 | .96 | 1.5 | 1.0 | 32 |

| RGD-117 | 28 | 2.5 | 4.1 | .82 | 2.8 | 21 | .42 | 1.1 | 1.7 | 56 |

| RGD-124 | 32 | 2.6 | 5.0 | 2.3 | 6.5 | 23 | .71 | 1.5 | 2.1 | 67 |

| RGD-190 | 40 | 2.8 | 7.0 | 5.6 | 12.6 | 25 | .50 | 1.3 | 2.4 | 75 |

Note: Permittivity = e’ – je” Permeability = m’ – jm”

dB/cm represents attenuation within the material These values are nominal and should not be used for writing specifications without consulting.

AVAILABILITY

Standard product sizes for all grades are flat sheets 12 x 12 in (305 x 305 mm), available in several standard thicknesses from 0.25 to 3.0 inches (6.4 to 76mm). The sheets are normally supplied “as cast”, approx. 0.05 to 0.10 inches over the nominal thickness, with a skin that must be machined off.

Cuming Microwave can supply RGD sheets precision machined to thickness, as well as machined to rods, other shapes, and can machine parts to engineering drawings. Consult one of our sales engineers.

Specify the product as C-RAM RGD-nnn axbxc, where nnn is the grade, and a, b, c are the dimensions, for example: C-RAM RGD-124 12x12x1.0 inch. Material will be supplied as cast unless specified otherwise.