No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Truncated Pyramidal Microwave Absorber

- EMC Test Equipment

- Transient Generators

- RF Power Amplifiers

- DC - 300 kHz RF Amplifiers

- 10 kHz - 250 MHz RF Amplifiers

- 10 kHz - 400 MHz RF Amplifiers

- 10 kHz - 1 GHz RF Amplifiers

- 80 MHz - 1 GHz RF Amplifiers

- 1 GHz - 2 GHz RF Amplifiers

- 700 MHz - 4.2 GHz RF Amplifiers

- 1 GHz - 6 GHz RF Amplifiers

- 2 GHz - 8 GHz RF Amplifiers

- 6 GHz - 18 GHz RF Amplifiers

- 18 GHz - 40 GHz RF Amplifiers

- Pulse Amplifiers

- RF Field Strength Probes & Meters

- RF Conducted Immunity

- EMC Receivers/EMI Analyzers

- EMC Antennas

- Coupling Decoupling Networks (CDN's)

- Line Impedance Stabilization Networks (LISN's)

- RF Test Equipment

- EMC Probes

- EMC Measurement & Equipment Software

- Power Supplies

- Electrical Safety Analyzers

- High Precision Laboratory Power Analyzers & Meters

- Anechoic Chambers

- Over-the-Air (OTA) Test Chambers

- EMI RF Shielded Tent Enclosures

- RF Shielded Rooms

- EMC Absorber

- Positioning Equipment

- EMC/EMI Test Setup

- GTEM Cells / TEM Cells

- Reverberation Chambers

- Used RF Anechoic Chambers

- EMC Chamber Filters

- EMC Chamber Shielding Gaskets

- RF Shielded Doors

- Anechoic Chamber Accessories

- Fully Anechoic (FAR) Test Chambers

- Manufacturers

- 3ctest

- AE Techron

- AH Systems

- Amplifier Research

- Boonton

- Com-Power

- Diamond Engineering

- EM Test (Ametek CTS)

- EMC Partner

- EMC Test Design

- Empower High Power RF Amplifiers

- ETS-lindgren

- Log Periodic Dipole Array Antenna

- Near Field Probe Sets

- Double Ridge Horn Antennas

- Biconical Antennas

- Quad Ridge Horn Antennas

- Electric Field Probes

- GTEM's

- Positioners & Tripods

- Loop Antennas

- Biconilog Antennas

- LISN's (Line Impedance Stabilization Network)

- Shielded Enclosures/Rooms

- Monopole Antennas

- Field Generating Antennas

- Fischer Custom Communications

- Haefely Hipotronics

- Haefely EFT/Burst Immunity Test Systems

- Haefely Surge Combination Wave Test Systems

- Haefely Surge Damped Oscillating Wave Test Systems

- Haefely Electrostatic Discharge Test Systems (ESD)

- Haefely Surge Ring Wave Test Systems

- Haefely Surge Telecom Wave Test Systems

- Haefely Magnetic Field Test Systems

- Haefely CDN's (Coupling/Decoupling Networks)

- IFI Amplifiers

- Keysight (Agilent)

- MVG - Microwave Vision Group

- PMM / Narda

- Rohde & Schwarz RF Test Equipment

- Rohde & Schwarz Broadband RF Amplifiers

- Rohde & Schwarz Spectrum Analyzers

- Rohde & Schwarz Compliant EMI Test Receivers

- Rohde & Schwarz Isotropic RF Probes

- Rohde & Schwarz RF Signal Generators

- Rohde & Schwarz RF Switches

- Rohde & Schwarz Oscilloscopes

- Rohde & Schwarz RF Power Meters

- Rohde & Schwarz RF Power Sensors

- Schloder

- Schwarzbeck Mess-Elektronik

- Schwarzbeck Antennas

- Schwarzbeck Automotive Antennas

- Schwarzbeck Broadband Horn Antennas

- Schwarzbeck Biconical Antennas

- Schwarzbeck Logarithmic Periodic Broadband Antennas

- Schwarzbeck Stacked Log-Periodic Broadband Antennas

- Schwarzbeck Biconic Log-Periodic Antennas

- Schwarzbeck Dipole Antennas

- Schwarzbeck Rod Antennas

- Schwarbeck Antenna Baluns / Holders

- Schwarzbeck LISN Line Impedance Stabilisation Networks

- Schwarbeck Decoupling & Absorbing Clamps

- Schwarzbeck Field Probes

- Schwarzbeck Helmholtz Coils

- Schwarzbeck Antenna Masts

- Schwarzbeck Coupling/Decoupling Networks

- Schwarzbeck Antennas

- Solar Electronics

- Teseq (Schaffner)

- Teseq Automotive Transient Generators

- Teseq RF Test Equipment

- Teseq EFT/Burst Generators

- Teseq RF Immunity Generators

- Teseq ESD Guns

- Teseq Surge Generators

- Teseq Harmonics & Flicker Solutions

- Teseq Dips, Interrupts & Variations Equipment

- Teseq Ring Wave Generators

- Teseq Oscillatory Waves Generators

- Teseq Absorbing Clamps / Ferrite Tube

- Teseq EMC Antennas

- Teseq Current Probes

- Teseq Coupling Networks

- Thermo Keytek

- Vicreate

- Compliance Standards

- International (IEC/EN)

- EN/IEC 61000-3-2

- EN/IEC 61000-3-3

- IEC 61000-3-11

- IEC / EN 610000-3-12

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-7

- EN/IEC 61000-4-8

- EN/IEC 61000-4-9

- EN/IEC 61000-4-10

- EN/IEC 61000-4-11

- EN/IEC 61000-4-12

- EN/IEC 61000-4-16

- EN/IEC 61000-4-18

- EN/IEC 61000-4-19

- EN/IEC 61000-4-20

- EN/IEC 61000-4-21

- EN/IEC 61000-4-29

- EN/IEC 61000-4-31

- IEC 61000-4-39

- EN/IEC 62132

- SEMI F47 Voltage Sag Immunity

- Product Standards

- Military & Aerospace Standards

- Automotive EMC Standards

- CISPR Standards

- Telecom Testing

- ANSI/IEEE Standards

- FCC Part 15

- FCC Part 30

- International (IEC/EN)

- Application/Test Type

- Radiated Immunity

- Bulk Current Injection Testing

- RF Emissions Testing

- Conducted Immunity

- Conducted Emissions

- Antenna Pattern Measurement

- CE Mark Testing

- Intentional Radiator Testing

- Pulsed HIRF Radar

- Over-the-Air (OTA) Testing

- 5G Test Solutions

- Automotive EMC

- SAR Measurement Equipment

- Radiated Emissions

- Battery Simulator Test Equipment

- Services

- Clearance

Viewed products

-

Cuming Microwave C-RAM...

Series of two part liquid RTV...

Cuming Microwave C-RAM KRS Iron Filled Silicone Casting Resin For RF Loads

New

- Series of two part liquid RTV silicone casting resin kits

- Can be used to mold wave guide terminations, attenuators, loads, RF gaskets and other radar absorber parts

- Will cure and adhere to itself or to other silicone surfaces

- It will release from most substrates

PDF Downloads

Test Equipment Description

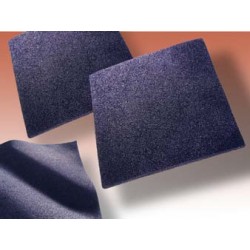

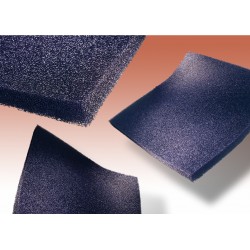

The C-RAM KRS is a series of two part liquid RTV silicone casting resin kits which can be used to mold wave guide terminations, attenuators, loads, RF gaskets, and other radar absorber parts. When cured, the material converts to a flexible, high temperature silicone rubber. Parts cast from C-RAM KRS have the same performance as parts machined from bars or sheets of C-RAM RGD-S (See Technical Bulletin 330-2). C-RAM KRS is available in the same grades as C-RAM RGD-S.

C-RAM KRS will cure and adhere to itself or to other silicone surfaces, however, it will release from most substrates. If adhesion is required, an application of C-PRIME 215 is recommended.

TYPICAL PROPERTIES

Cured parts of C-RAM KRS have essentially the same properties as the equivalent grade of C-RAM RGD-S.

| Specific Gravity: | |

| KRS-124 | 4.5 |

| KRS-117 | 4.2 |

| KRS-116 | 3.7 |

| For C-RAM KRS-124, the following properties apply: | |

| Thermal Expansion per °C | 60 x 10-6 |

| Therm. Conductivity | .0021 cal-cm/sec-cm2-°C (6.0 BTU-in/hr-ft2-°F) |

| Service Temperature | -55 to +200 °C (-65 to +400 °F) |

| Hardness, Shore A | 75 |

| Water Absorption, 24 hrs | <0.1% |

| Volume Resistivity, ohm-cm | >1010 |

| Dielectric Strength, kv/mm | >400 (>100 V/mil) |

METHOD OF APPLICATION

- Prepare mold or cavity to be filled. C-RAM KRS will adhere to most silicones and release well from most other substrates. If adhesion is desired, use a thin coat of C-PRIME-215. In molding operations where the highest release is required, a wax mold release will be beneficial.

- Kits are supplied as Part A (silicone resin plus filler) and Part B (curing agent). Stir the contents of part A thoroughly, preferably using a power mixer, to disperse settled filler.

- Measure out the material required, combine Parts A and B in the proportions listed below. Mix the two parts, thoroughly scraping the sides and bottom. A power mixer is preferred. Pot life is approximately 1 hour.

| Parts by weight | KRS-124 | -117 | -116 |

| A | 100 | 100 | 100 |

| B | 1.08 | 1.30 | 1.70 |

- Best results are obtained by vacuum deairing the mixture. Pour the material into the prepared mold or cavity taking care not to entrap air.

- Cure the material at room temperature overnight, or at 80°C (175°F) for three hours. At usage temperatures above 120°C (250°F), a post cure at or above the usage temperature for approximately eight hours is recommended.

C-RAM materials are safe to use, provided care is taken to protect eyes and avoid excessive skin contact and breathing of vapors. Consult the Materials Safety Data Sheet for details.

AVAILABILITY

C-RAM KRS is available in two-part kits in the following sizes:

3 lb. pint (1.35 kg total weight)

6 lb. quart (2.7 kg total weight)

25 lb. gallon (11.3 kg total weight)

Shelf life is at least 12 months when stored in unopened containers. It may be necessary to power stir the contents as settling may occur. Completed castings or machined pads are available as C-RAM RGD-S.