No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Antenna Test Turntables

- EMC Test Equipment

- Transient Generators

- RF Power Amplifiers

- DC - 300 kHz RF Amplifiers

- 10 kHz - 250 MHz RF Amplifiers

- 10 kHz - 400 MHz RF Amplifiers

- 10 kHz - 1 GHz RF Amplifiers

- 80 MHz - 1 GHz RF Amplifiers

- 1 GHz - 2 GHz RF Amplifiers

- 700 MHz - 4.2 GHz RF Amplifiers

- 1 GHz - 6 GHz RF Amplifiers

- 2 GHz - 8 GHz RF Amplifiers

- 6 GHz - 18 GHz RF Amplifiers

- 18 GHz - 40 GHz RF Amplifiers

- Pulse Amplifiers

- RF Field Strength Probes & Meters

- RF Conducted Immunity

- EMC Receivers/EMI Analyzers

- EMC Antennas

- Coupling Decoupling Networks (CDN's)

- Line Impedance Stabilization Networks (LISN's)

- RF Test Equipment

- EMC Probes

- EMC Measurement & Equipment Software

- Power Supplies

- Electrical Safety Analyzers

- High Precision Laboratory Power Analyzers & Meters

- Anechoic Chambers

- Over-the-Air (OTA) Test Chambers

- EMI RF Shielded Tent Enclosures

- RF Shielded Rooms

- EMC Absorber

- Positioning Equipment

- EMC/EMI Test Setup

- GTEM Cells / TEM Cells

- Reverberation Chambers

- Used RF Anechoic Chambers

- EMC Chamber Filters

- EMC Chamber Shielding Gaskets

- RF Shielded Doors

- Anechoic Chamber Accessories

- Fully Anechoic (FAR) Test Chambers

- Manufacturers

- 3ctest

- AE Techron

- AH Systems

- Amplifier Research

- Boonton

- Com-Power

- Diamond Engineering

- EM Test (Ametek CTS)

- EMC Partner

- EMC Test Design

- Empower High Power RF Amplifiers

- ETS-lindgren

- Log Periodic Dipole Array Antenna

- Near Field Probe Sets

- Double Ridge Horn Antennas

- Biconical Antennas

- Quad Ridge Horn Antennas

- Electric Field Probes

- GTEM's

- Positioners & Tripods

- Loop Antennas

- Biconilog Antennas

- LISN's (Line Impedance Stabilization Network)

- Shielded Enclosures/Rooms

- Monopole Antennas

- Field Generating Antennas

- Fischer Custom Communications

- Haefely Hipotronics

- Haefely EFT/Burst Immunity Test Systems

- Haefely Surge Combination Wave Test Systems

- Haefely Surge Damped Oscillating Wave Test Systems

- Haefely Electrostatic Discharge Test Systems (ESD)

- Haefely Surge Ring Wave Test Systems

- Haefely Surge Telecom Wave Test Systems

- Haefely Magnetic Field Test Systems

- Haefely CDN's (Coupling/Decoupling Networks)

- IFI Amplifiers

- Keysight (Agilent)

- MVG - Microwave Vision Group

- PMM / Narda

- Rohde & Schwarz RF Test Equipment

- Rohde & Schwarz Broadband RF Amplifiers

- Rohde & Schwarz Spectrum Analyzers

- Rohde & Schwarz Compliant EMI Test Receivers

- Rohde & Schwarz Isotropic RF Probes

- Rohde & Schwarz RF Signal Generators

- Rohde & Schwarz RF Switches

- Rohde & Schwarz Oscilloscopes

- Rohde & Schwarz RF Power Meters

- Rohde & Schwarz RF Power Sensors

- Schloder

- Schwarzbeck Mess-Elektronik

- Schwarzbeck Antennas

- Schwarzbeck Automotive Antennas

- Schwarzbeck Broadband Horn Antennas

- Schwarzbeck Biconical Antennas

- Schwarzbeck Logarithmic Periodic Broadband Antennas

- Schwarzbeck Stacked Log-Periodic Broadband Antennas

- Schwarzbeck Biconic Log-Periodic Antennas

- Schwarzbeck Dipole Antennas

- Schwarzbeck Rod Antennas

- Schwarbeck Antenna Baluns / Holders

- Schwarzbeck LISN Line Impedance Stabilisation Networks

- Schwarbeck Decoupling & Absorbing Clamps

- Schwarzbeck Field Probes

- Schwarzbeck Helmholtz Coils

- Schwarzbeck Antenna Masts

- Schwarzbeck Coupling/Decoupling Networks

- Schwarzbeck Antennas

- Solar Electronics

- Teseq (Schaffner)

- Teseq Automotive Transient Generators

- Teseq RF Test Equipment

- Teseq EFT/Burst Generators

- Teseq RF Immunity Generators

- Teseq ESD Guns

- Teseq Surge Generators

- Teseq Harmonics & Flicker Solutions

- Teseq Dips, Interrupts & Variations Equipment

- Teseq Ring Wave Generators

- Teseq Oscillatory Waves Generators

- Teseq Absorbing Clamps / Ferrite Tube

- Teseq EMC Antennas

- Teseq Current Probes

- Teseq Coupling Networks

- Thermo Keytek

- Vicreate

- Compliance Standards

- International (IEC/EN)

- EN/IEC 61000-3-2

- EN/IEC 61000-3-3

- IEC 61000-3-11

- IEC / EN 610000-3-12

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-7

- EN/IEC 61000-4-8

- EN/IEC 61000-4-9

- EN/IEC 61000-4-10

- EN/IEC 61000-4-11

- EN/IEC 61000-4-12

- EN/IEC 61000-4-16

- EN/IEC 61000-4-18

- EN/IEC 61000-4-19

- EN/IEC 61000-4-20

- EN/IEC 61000-4-21

- EN/IEC 61000-4-29

- EN/IEC 61000-4-31

- IEC 61000-4-39

- EN/IEC 62132

- SEMI F47 Voltage Sag Immunity

- Product Standards

- Military & Aerospace Standards

- Automotive EMC Standards

- CISPR Standards

- Telecom Testing

- ANSI/IEEE Standards

- FCC Part 15

- FCC Part 30

- International (IEC/EN)

- Application/Test Type

- Radiated Immunity

- Bulk Current Injection Testing

- RF Emissions Testing

- Conducted Immunity

- Conducted Emissions

- Antenna Pattern Measurement

- CE Mark Testing

- Intentional Radiator Testing

- Pulsed HIRF Radar

- Over-the-Air (OTA) Testing

- 5G Test Solutions

- Automotive EMC

- SAR Measurement Equipment

- Radiated Emissions

- Battery Simulator Test Equipment

- Services

- Clearance

Viewed products

-

Maturo DYN 4WD_I...

Integrated dynamometer into...

View larger

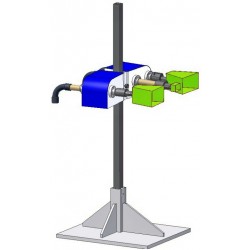

View larger Maturo DYN 4WD_I Dynamometer Into Turntable

New

- Integrated dynamometer into turntable

- For use in anechoic chambers for EMI and EMC measurements

- 2 active axles, for cars with rear /front – or four wheel drive

- 4 independently controllable roller pairs

- Independent rotation of dynamometer and turntable

- Various designs and specifications on customer request available

- Cooling fan, robot system, exhaust extraction system, and more available

PDF Downloads

Test Equipment Description

The Dynamometer DYN 4WD is constructed as a chassis dynamometer, which can be integrated into a turntable. Two active elements are used for vehicles with rear/front or four- wheel drive. The four roller pairs are independently operational. Each vehicle wheel is driven by a separate motor/generator system. It can be used for acceleration/retardation and in an endurance mode.

EMI/EMC

The Dynamometer DYN 4WD is prepared to be used in an anechoic chamber for EMI and EMC measurements. All electronic components are located in a separate box, which is shielded, and radio interference suppressed. The RF- Emission is more than 15 dB under limit “B” on CISPR 12 and CISPR 25. The immunity against continuous field strength up to 200 V/m is guaranteed.

Control Unit

Each active element has two micro controller to control the frequency inverters and for the speed measurement system. The element is connected to the system controller via fibre optic links. The system controller PC is equipped with an IEEE or LAN interface for remote control with a measurement software.

Safety and Emergency Function

The maximum speed is limited by inverter function controller and by the internal micro controller. The temperature on the motors and inside the electronic box is being watched. Two emergency switches are located close to the stand and in the control room. In case of an emergency, the motor power will be switched off and the motors come to a standstill.

Signal Lamp

| The signal lamp in control room shows the state of the dynamometer: Green continuous -> Emergency is ok |

Rollers

The rollers are static heaved up to 2000 rpm and flame-coated.

The surface of the rollers is comparable with road surface.

Balance quality: Q 2.5 according to VDI 2060

Fig.: Double roller system

ABS and ESP tests

The dynamometer DYN 4WD allows ABS and ESP testing of vehicles up to an acceleration or deceleration of 1.0 g (10 m/s²).

Structure:

The 4 independent roller pairs of the dynamometer are integrated into a “self-contained” frame, which minimizes the dynamic energy output to the turntable. The frame itself is placed into the turntable as pre-assembled assembly group for an easy installation of the system.

Wheel Base

Independent adjustment of the front and rear axle allows to adjust the position of the vehicle in respect to the centre of the turntable. Adjusting speed: approx. 20 mm/s Positioning accuracy: +/- 2 mm Operation of the wheel base adjustment is only possible at a standstill of the dynamometer.

Fig.: Motor for wheelbase adjustment

Shutter system in track area

An overlapping “roller-type shutter” connection between the axles avoid gaps at the surface in every position of the wheelbase. Each element is connected with conductive material to the turntable surface and the next element. The max. permissible axle load in the track area is 2000 kg.

Fig.: Shutter System F

Fixing Elements

The system is equipped with four lashing straps to fixing of the vehicle while running. Spring hooks allow an easy connection to the four fastening bolts. The fixing elements are integrated into the structure of the system and are adjustable to the specific vehicle sizes. The straps are made of electrically neutral material. Length adjustment: from 1.0 to 6.0 m Tensile strength: 5000 N

Fig.: Fixing system

Single-wheel drive for motorcycles testing

The Dynamometer DYN 4WD is equipped with a function for testing motorcycles or any other motorised two-wheeler. The system and the software allow the selection of the operation of only one single roller.

Fig.: Testing of motorcycles

Cooling fan system

Shielded fans provide a sufficient cooling for the tyres and the motor of the vehicle under test.

A removable plastic air scoop on top of the turntable is used to detour the airflow.

The fan speed can be set either stepwise to the roller speed (up to 60 km/h) or to a constant speed by the dyno software.

Installation of the cooling fans is below the cover

Wind speed: 60 km/h

Air flow: 10.000 m³/h

Fig.: Cooling fan system

Software and functions of the Dynamometer

The included software contains the following functions:

- Emergency stop

- Start cycle / stop cycle

- Speed control of the rollers

- Speed control of the ventilator

- Force at the rim (in Nm)

- Distance gone from the start of the cycle (in km)

- Cycle recording (profile)

To allow the following test cycles:

- Constant velocity

- Velocity gradient

- Street (road) simulation

- Simulation of uphill and downhill driving

- ABS, ESP testing with acceleration/deceleration of up to 1.0g

- Single-wheel drive fort wo-wheelers

The software includes:

- PC-Controller with keyboard, mouse and monitor

- The DYN-Software is pre-installed at the PC

Software Description (Example)

Operation modes:

The following modes are available:

- Constant Velocity - "ConVelo" driving with constant speed

- Gradient Mode - "GarVelo" performing a driving profile; e.g. for ABS testing

- Road Simulation - "RoadSim" for road simulation with counter torque

- Measurements

- Block Rolls - “Block Rolls” to drive in and out with car

Constant Velocity:

At the operating mode “ConVelo” it is possible to set a certain speed, acceleration and deceleration. These values are limited by the limits of the dynamometer or the limits of the used vehicle.

This mode can be activated with the “Start” key and stopped with the “Stop” key.

The current values of speed and torque are displayed for each motor.

The speed curve is displayed as a graph.

| Technical Data | |

| Permissible axle load | 2.000 kg (each axle) |

| Max speeds for cars | 100 km/h |

| Speed measurement accuracy | +/- 0.1 km/h |

| Wheel track between the front wheels | 1200 to 2100 mm |

| Wheelbase between the front and rear wheel | 2000 to 3200 mm |

| Diameter car wheels | min. 400 mm max. 800 mm |

| Diameter rollers (4 roller pairs) | 240 mm |

| The surface of the rollers is flame-coated The rollers are static heaved up to 2000 rpm | |

| Specifications | Active axles |

| 4 Asynchrony Servomotors/-generators | each 22 kW (total 44 per axle) |

| 4 Vector frequency inverter | each 37 kVA |

| Voltage/current consumption 4 Break resistors cooled by fan | 2x 380-400 V/ 63 A/ 3phase |

| Acceleration/ deceleration | max. 1.0g from 10 to 60 km/h max. 0.5g from 10 to 100 km/h |

| EMC Performances | |

| Emission | |

| More than 15 dB under the limits of CISPR 12 and CISPR 25 | |

| Frequency range | 30 MHz – 1 GHz |

| Measurement distance | 10 m |

| Emission, Electrical | |

| More than 15 dB under the limit of SAE J551-5 2004-01, GB/T 18387-2008 | |

| Frequency range | 9 KHz – 30 MHz |

| Measurement distance | 3 m |

| Emission, Magnetic | |

| More than 10 dB under limit of SAE J551-5 | 2004-01, GB/T 18387-2008 |

| Frequency range | 9 KHz – 30 MHz |

| Measurement distance | 3 m |

| Immunity | |

| Continuous field strength | 200 V/m |

| Frequency range | 10 kHz – 18 GHz |

| System Controller | PC with serial communication to the dynamometer and Dynamo-Software |